How to Replace a Solenoid Valve

Jul 9th 2024

A solenoid valve is a crucial component of an irrigation system that controls the water flow to various irrigation zones. The voltage applied to the coil causes the valve to open and allows water to flow. When a solenoid valve fails to run properly, it can lead to multiple issues, such as overwatering or dry spots. If the valve seals are broken or damaged, you will need to replace the valve.

This blog post covers replacing an irrigation valve solenoid to ensure your irrigation system runs smoothly and efficiently. If you're replacing the valve the first time, you will be able to complete the project in a couple of hours as long as you have all the required tools and materials.

When to Replace a Solenoid Valve

The answer to this question depends on the valve type and application. For instance, in demanding applications requiring heavy usage and minimum lubrication, your solenoid valve may need replacing within 100,000 cycles. In contrast, a well-maintained and lubricated valve can last millions of cycles. One cycle of the valve is one watering interval.

Sometimes, the valve acts up due to dirt or debris building up in its interior parts. If your valve is doing so, you should start by cleaning the clogged areas that could be causing the valve to fail. The top (guts) of the valve consists of the solenoid, diaphragm, and plastic casting. There is also a port at the top and a filter screen in the diaphragm that can get clogged.

Poor wiring also causes most valve problems. If the solenoid valve isn't working correctly, inspect the wiring to ensure all connections are correct and secure. Remember always to use weatherproof wire connectors to connect the wires.

Related Post: Landscape Wire Connectors: Everything You Need to Know

Generally, if your valve shows signs of wear and damage, it is likely time for its replacement. Replacing a valve can be less expensive than paying maintenance and labor costs. However, good valve maintenance practices are essential to prevent valve failure and costly repairs.

The common causes of solenoid valve failure that may wear the valve to the replacement point include:

- Incorrect voltage

- High water pressure

- Direct contact with water

- Sediment damage

- Significant change in temperature

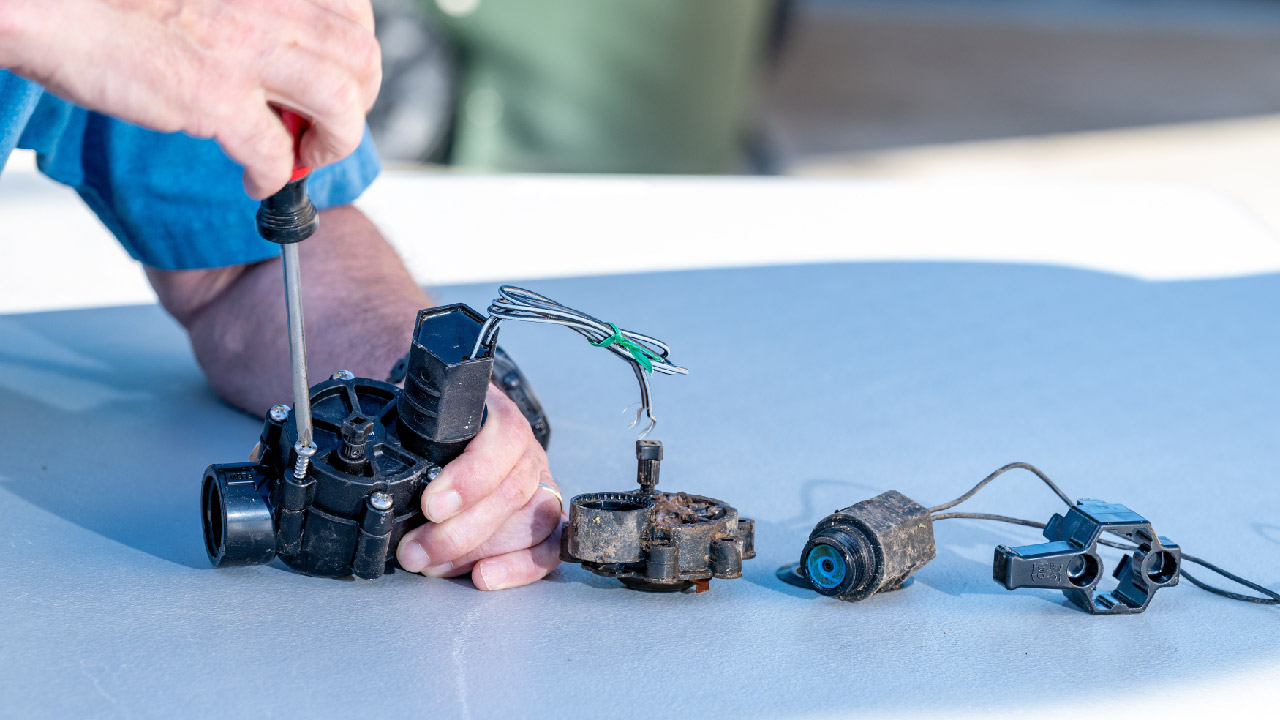

Replacing the Solenoid on an Irrigation Valve

Here are some steps you can follow to replace an irrigation valve solenoid:

1. Turn off the water supply.

Turn off the main water supply to the irrigation system and relieve pressure in the line by turning the solenoid halfway.

2. Disconnect the wires.

Cut or unscrew the wire nuts to disconnect the wires from the solenoid. Don't use the old connections as they may be corroded.

3. Remove the solenoid.

Turn the solenoid counterclockwise to unscrew it from the valve body. Be careful not to get dirt in the opening.

4. Install the new solenoid.

Turn the new solenoid clockwise until it's hand tight. Don't overtighten it, as this could damage the valve.

5. Reconnect the wires.

Strip back about half an inch from each wire and splice a new end. Connect the common wires to the wire coming from the solenoid.

6. Turn the water supply back on.

Turn the solenoid counterclockwise a quarter turn to allow water flow.

How to Replace a Solenoid Valve

There are two ways to replace a solenoid valve: replace the top with new parts or cut the entire valve and replace it with a new one. A few parts of the valve can fail, including the solenoid, diaphragm, and ports located on the top. Valve bodies are durable. Unless the body is damaged, it is almost safe to go.

It is best to find the same brand and model of solenoid valve so you can easily swap the top parts of the faulty valve and replace them with new parts from the new unit. Swapping out the internal parts with a new model is the easiest way to replace a valve. However, it is possible that the manufacturer no longer makes that valve model.

If you want to replace the valve immediately and don't have time to search for the same model, you can replace the whole valve.

Tools and Materials Required

When choosing a new solenoid valve for replacement, consider the valve's pressure range, operating voltage, flow rate, and compatibility with your irrigation system. Before starting the project, gather the following tools and materials.

- Replacement solenoid valve

- Adjustable wrench

- Screwdriver

- Wire nuts

- Wire stripper

Step-by-step Process to Replace a Solenoid Valve

1. Turn Off the Water Supply

Shut off the water supply to the affected zone or the entire irrigation system.

2. Turn Off Power

Turn off the electrical power to the system where the valve is located. Work in a dry environment to avoid any electrical hazards.

3. Locate the Solenoid Valve

Find the location of the faulty solenoid valve in the system. Run a manual test from the controller to determine which valve needs replacement, or you can look for malfunctioning signs such as leakage.

4. Disconnect the Wiring

Carefully disconnect the wiring connected to the solenoid.

5. Remove the Old Valve

Use a wrench to unscrew the old solenoid valve from the valve body by turning it counterclockwise. If the valve is threaded into tubing, use a pipe wrench or adjustable pliers to remove it.

6. Install the New Solenoid Valve

Insert the new valve into the pipe. Double-check that the new valve is in the correct position and direction. Arrows on the valve body indicate the water flow. Make sure the new valve's arrows point in the same direction as the old one.

7. Reconnect the Wiring

Reconnect the electrical wires from the valve to the irrigation controller using wire connectors for a secure connection.

8. Test the New Solenoid Valve

Turn the water supply on and restore the power to test the valve. Manually run the irrigation system to confirm the new valve is working correctly. Check connections for leaks. If there are any, tighten the connections.

Solenoid Valve Troubleshooting Tips

Here are some troubleshooting tips to handle issues after replacing the valve.

- Inspect the wiring connections for loose or damaged wires. Re-strip the wire ends and reconnect them with weatherproof wire connectors.

- Check the new solenoid valve's pressure, and flow rate to ensure it is compatible with your system.

- Check that the solenoid valve is oriented in the correct direction.

- Inspect the valve for any debris or dirt blocking its operation.

Tips for Extending Solenoid Valve Lifespan

- Regularly inspect the irrigation system for leaks, signs of wear, and damaged components. Address issues promptly to avoid bigger problems and costly repairs.

- Perform seasonal irrigation system maintenance, such as adjusting sprinklers, cleaning filters and sprayers, winterizing sprinklers, and ensuring proper water pressure. This upkeep helps ensure optimal irrigation system performance.

- Flush the system frequently to remove dirt and sediment that can cause clogs and wear in solenoid valves.

- Keep the system pressure and flow rate within the valve specifications to avoid overloading it.

Conclusion

Solenoid valves are a key component of any irrigation valve. An efficient, smoothly functioning irrigation system requires a properly functioning valve. By diagnosing a faulty solenoid valve and following the above steps, you can successfully replace a damaged solenoid valve and restore the optimal performance of your system. Finally, regularly inspect and maintain the irrigation system to prevent future issues and extend the life of your irrigation valves for a healthy, beautiful landscape.

DripWorks offers a wide range of durable and affordable solenoid valves that will automate your irrigation system and ensure it runs efficiently. We carry both AC and DC-powered irrigation valves to suit every landscaper's needs.